Imagine a world where your farm equipment runs smoothly season after season, significantly reducing downtime and costly repairs. Sounds ideal, doesn’t it?

The secret to achieving this lies in a simple yet effective strategy: regular maintenance. But where do you start, and how can you ensure you’re covering all the bases? This is where a comprehensive farm equipment maintenance checklist comes into play.

You’ll discover practical steps to prolong the life of your machinery, ensuring it remains as reliable as the day you bought it. We’ll guide you through essential tasks that not only enhance performance but also save you money in the long run. By the end of this post, you’ll have the knowledge to keep your equipment in peak condition, making your farming operations smoother and more efficient. Dive in to learn how you can maximize the lifespan of your valuable assets and boost your farm’s productivity.

Regular Inspection Routine

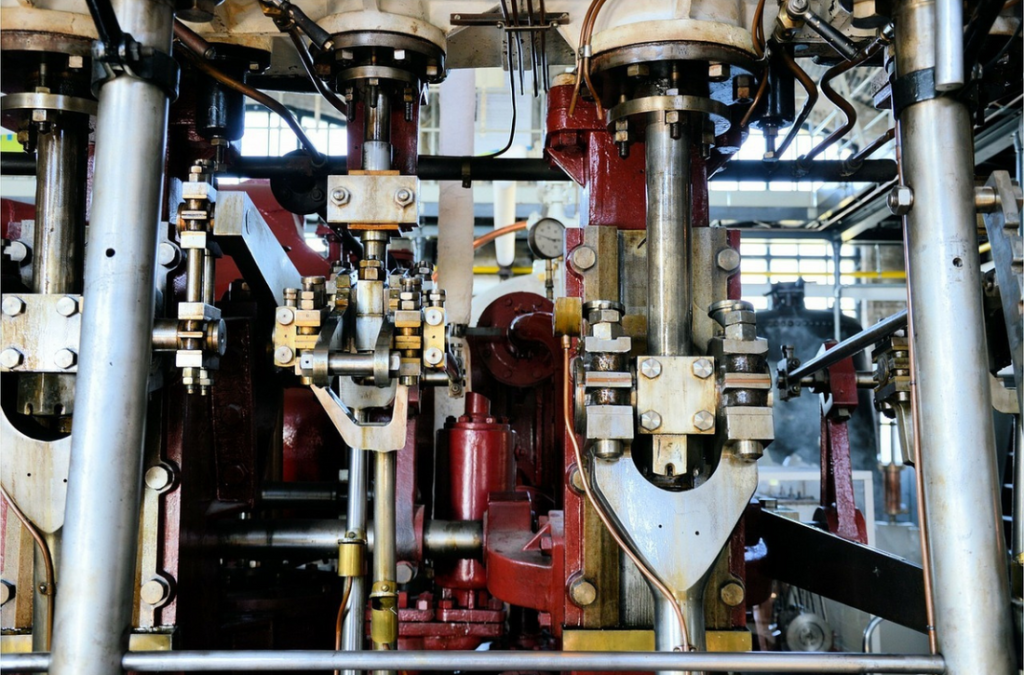

Regular inspection of farm equipment ensures its longevity and reliability. A structured routine helps identify potential issues early. This proactive approach minimizes costly repairs and downtime. It also boosts the efficiency of farm operations. Consistent checks can prevent unexpected breakdowns. They help maintain the value of the equipment over time. Let’s explore essential elements of a regular inspection routine.

Inspect Fluids And Lubricants

Check oil, hydraulic fluid, and coolant levels regularly. Low levels can harm machinery. Ensure all parts are well-lubricated. This reduces friction and wear. It also helps avoid overheating.

Check Tires And Wheels

Inspect tire pressure and tread condition. Look for signs of wear or punctures. Properly inflated tires enhance safety and efficiency. Secure all wheel bolts and nuts tightly.

Examine Belts And Hoses

Look for cracks or frays in belts. Damaged belts can snap during use. Inspect hoses for leaks or blockages. Replace worn-out belts and hoses promptly.

Test Electrical Systems

Ensure all lights and indicators function properly. Check battery health and connections. Clean any corroded terminals. Proper functioning ensures safety and reliability.

Assess Filters And Air Intakes

Clean or replace air and fuel filters regularly. Clogged filters reduce engine performance. Ensure air intakes are free from debris. This helps maintain engine efficiency.

Inspect Brakes And Steering

Test brake responsiveness and steering control. Look for any signs of stiffness or lag. Regular checks can prevent accidents. Ensure all parts operate smoothly and safely.

Cleaning And Lubrication

Farm equipment needs regular cleaning and lubrication for long life. Dust and dirt can damage machinery over time. Proper cleaning removes these particles. Lubrication prevents rust and reduces wear. Both tasks ensure smooth operation and extend lifespan.

Cleaning Tools And Techniques

Choose the right tools for cleaning farm equipment. Use soft brushes to avoid scratches. Water hoses help remove stubborn dirt. Pressure washers clean hard-to-reach areas. Avoid harsh chemicals that may damage parts. Clean equipment after each use for best results.

Lubrication Essentials

Lubrication reduces friction in moving parts. Use manufacturer-recommended lubricants. Check manuals for specific requirements. Apply lubricants to joints and bearings. Grease fittings should be properly maintained. Regular lubrication prevents breakdowns.

Frequency Of Cleaning And Lubrication

Set a schedule for cleaning and lubrication. Daily checks are crucial for heavily used equipment. Weekly cleaning suffices for less-used machinery. Lubricate parts weekly or monthly, as needed. Follow recommendations from equipment manuals.

Safety Precautions

Safety is vital when cleaning and lubricating. Wear protective gear like gloves and goggles. Work in well-ventilated areas. Ensure equipment is turned off before cleaning. Use ladders carefully to reach higher areas. Proper safety measures prevent accidents.

Benefits Of Proper Maintenance

Proper cleaning and lubrication enhance equipment performance. Reduced friction leads to less fuel consumption. Cleaner machines operate more efficiently. Well-lubricated parts last longer. Maintenance saves money in the long run.

Seasonal Equipment Adjustments

Farm equipment requires regular care for optimal performance and longevity. Seasonal equipment adjustments play a crucial role in this process. Different seasons bring unique challenges for machinery. Preparing equipment for these changes ensures efficiency and reduces breakdowns.

Seasonal adjustments can save money in the long run. They protect your investment and keep your farm running smoothly. Let’s explore key adjustments needed for each season.

Winter Preparation

Winter conditions can be harsh on farm equipment. Inspect hydraulic systems for any leaks or damages. Frozen hydraulic fluid can cause serious issues. Check antifreeze levels in all machinery. Ensure batteries are fully charged to handle cold starts. Lubricate moving parts to prevent rust and wear. Store sensitive equipment indoors to shield from snow and ice.

Spring Tune-up

Spring signals the start of planting season. Ensure tractors and plows are ready for action. Replace worn-out tires for better traction on muddy fields. Clean out air filters to improve engine efficiency. Test all electrical systems for proper functioning. Examine belts and hoses for signs of wear. Check seeders for any blockages or damages.

Summer Adjustments

Summer heat can affect machinery performance. Inspect cooling systems for leaks or blockages. Clean radiators to prevent overheating. Monitor oil levels closely. Dust and debris can clog machinery. Regularly clean and lubricate to maintain operation. Check tire pressure frequently. Adjust for changes in temperature.

Fall Maintenance

Fall marks the harvest season. Equipment faces heavy workloads. Sharpen blades on harvesters for efficiency. Inspect chains and belts for wear. Replace damaged parts promptly. Clean grain carts and conveyors after use. Remove any leftover debris. Test brakes and steering for safety. Ensure lighting systems are functioning well. Days grow shorter in fall.

Storage And Protection Tips

Keep farm equipment working longer with proper storage and protection. Clean machines after use to prevent rust. Store tools indoors, away from moisture and pests. Regularly check for wear and repair parts promptly.

Proper storage and protection of your farm equipment can significantly extend its life. Imagine heading out to your shed, knowing every piece is just as you left it—clean, rust-free, and ready to use. These storage and protection tips will help you achieve that peace of mind. Let’s dive into the essentials that ensure your equipment remains in top-notch condition year-round.Regular Cleaning Before Storage

Before storing your equipment, make it a routine to clean it thoroughly. Dirt and debris can lead to rust and corrosion if left unchecked. A simple wash with water and mild soap can do wonders. After cleaning, ensure all parts are dry to prevent moisture from causing damage.Choose The Right Storage Location

Where you store your equipment can make a big difference. A dry, sheltered space like a barn or a shed is ideal. Avoid areas that are prone to flooding or excessive moisture. If indoor storage isn’t an option, consider using weather-resistant covers to protect your equipment from the elements.Use Protective Covers

Protective covers are more than just dust shields. They guard against moisture, UV rays, and pests. Investing in high-quality, breathable covers can prevent condensation, which is a silent killer of machinery. Ensure the covers fit well to keep every part of your equipment safe.Regular Inspections

Even in storage, equipment needs attention. Set a schedule to inspect your machines regularly. Look for signs of wear, rust, or pest infestations. Catching these early can save you from costly repairs later.Proper Tire Care

Tires can be easily overlooked, but they need care too. Inflate them to the recommended pressure before storing. This prevents flat spots and prolongs their life. Consider using tire jacks to take the weight off and avoid long-term damage.Lubrication And Fluid Checks

Before you store your equipment, check and refill all necessary fluids. Lubricate moving parts to prevent rusting and seizing. This small step can keep your machinery operating smoothly once it’s back in use.Rodent And Pest Control

Pests can wreak havoc on stored equipment. Mice and rats love to chew through wires and hoses. Use traps or repellents to keep them at bay. Regularly check for any signs of pest activity and take action immediately. Storing your equipment properly is a commitment, but one that pays off. By following these tips, you not only extend the life of your machinery but also ensure it’s ready when you are. Do you have any specific methods or tricks for storing your equipment? Share your insights in the comments!Conclusion

Regular maintenance extends farm equipment life. Follow the checklist diligently. Catch issues early to save money. Keep machines clean for better performance. Inspect parts regularly to avoid breakdowns. Lubricate moving parts to reduce wear. Check fluid levels to ensure smooth operation.

Tighten loose bolts for safety. Replace worn parts promptly to prevent damage. Use the right tools for repairs. Store equipment properly to protect it. Train workers on maintenance tasks. Prioritize safety and efficiency in all practices. Invest time now for long-term benefits.

Your farm thrives when equipment runs well. Stay committed to upkeep.