Are you trying to decide between manual labor and machine labor for your business or project? The decision can be daunting, but understanding the cost implications is crucial.

You might be wondering which option will save you more money or boost your productivity. We all want to make the best choice for our budget and goals. This article will break down the costs involved in both manual and machine labor, so you can make an informed decision.

Dive into this cost comparison to discover which option aligns best with your needs and priorities. Your path to smarter spending and efficient operations starts here!

Economic Factors

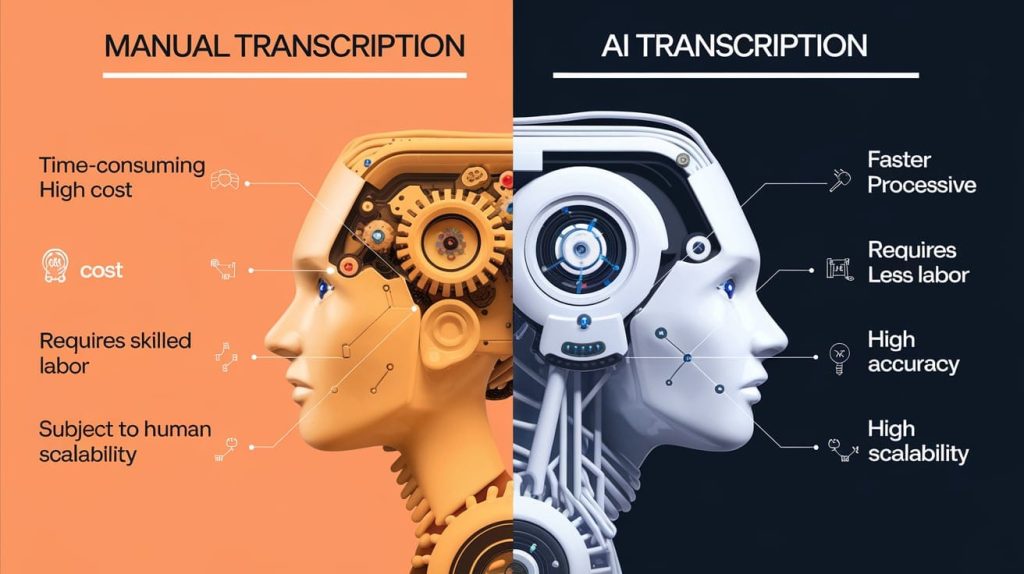

Comparing costs between manual and machine labor involves analyzing expenses like wages, equipment maintenance, and efficiency. Machine labor often reduces long-term costs due to automation. Manual labor can be more flexible but may lead to higher expenses over time.

Understanding the economic factors in the cost comparison between manual labor and machine labor is crucial for any business. It can significantly influence your bottom line and shape your operational strategies. Whether you’re a small business owner or a decision-maker in a large corporation, the financial implications of this choice can have long-lasting effects.Direct Costs

Direct costs are often the first thing that comes to mind. Manual labor involves paying wages, which can vary based on skill levels and location. Machines, on the other hand, require a one-time investment but also come with maintenance and operational expenses. Imagine you run a small manufacturing unit. Calculating the cost of employing ten workers versus investing in a single machine can provide a clear picture of immediate financial outlay. Which seems more affordable for your current budget?Long-term Financial Impact

The long-term financial impact of choosing between manual and machine labor can be significant. While machines might seem expensive initially, they often reduce operational costs over time. Manual labor, however, can lead to increased costs due to wage hikes and turnover. Consider a business that switched to automation five years ago. They noticed a gradual decline in their expenses related to training and recruitment. Are you thinking about where your business will be five years from now?Scalability And Flexibility

Scalability is another economic factor you can’t ignore. Machines can easily scale operations up or down. Manual labor, however, requires hiring or laying off workers, which can be costly and time-consuming. Think about a period of high demand in your business. Would you prefer to adjust a machine’s settings to increase output, or go through the hiring process? Which option saves you time and money?Risk Management

Risk management is essential in business. Machines can break down, leading to unexpected repair costs. Manual labor, while more flexible, poses risks like human error and workplace accidents. A friend of mine once faced a major machine breakdown that halted production for days. The cost of repairs was significant, but it highlighted the importance of having a balanced strategy. How do you balance these risks in your current setup?Government Incentives

Governments often offer incentives for businesses that automate. These can range from tax breaks to grants for purchasing machinery. Such incentives can make the initial investment in machines more appealing. A small business owner I know took advantage of a local government grant for automation. This reduced their upfront costs considerably. Have you explored the incentives available in your region? Understanding these economic factors can guide you in making informed decisions. What’s more important to you—immediate savings or long-term benefits? Balancing the pros and cons of manual versus machine labor can lead to smarter financial planning.

Efficiency And Productivity

Efficiency and productivity are key factors in any business operation. Comparing manual labor and machine labor reveals important insights into these aspects. Each method has its own strengths and weaknesses.

Manual Labor: Human Touch

Manual labor often relies on skill and experience. Workers can adapt quickly to unexpected changes. This flexibility can be crucial in dynamic environments. Human workers also bring creativity to problem-solving tasks.

Machine Labor: Precision And Speed

Machines offer consistent precision and speed. They perform repetitive tasks with ease and reliability. Machine labor reduces errors and waste. Automated processes streamline production, saving time and money.

Balancing Labor Types

Combining both labor types can be beneficial. Manual labor adds a personal touch to operations. Machine labor ensures efficiency and high productivity. A balanced approach optimizes overall performance.

Cost Implications

Machines may have higher upfront costs. Long-term savings can be significant. Manual labor involves ongoing expenses like wages and training. Consider efficiency gains when comparing costs.

Long-term Investment

Comparing costs between manual labor and machine labor reveals significant differences in efficiency and long-term expenses. Machines often reduce operational costs due to automation, while manual labor may lead to higher expenses over time. Evaluating these options helps businesses make informed investment decisions for sustainable growth.

Investing in labor, whether manual or machine, is a decision that impacts the future of your business. It’s not just about immediate costs but also about long-term benefits and sustainability. When you think about the future, which option truly adds value? Let’s dig into how each choice stands as a long-term investment.Cost Efficiency Over Time

Manual labor often comes with lower initial costs. You hire workers, pay wages, and manage tasks. But, think about future expenses like training, health benefits, and potential errors. Machines, on the other hand, demand upfront investment. However, their efficiency can reduce ongoing costs. They don’t require breaks, don’t call in sick, and consistently maintain quality. Over time, the reduction in operational hiccups can save you money.Scalability And Flexibility

How easily can your business scale with manual labor? Hiring more workers can be time-consuming and costly. It may also involve infrastructure changes. Machines offer a different kind of flexibility. Need to increase production? Add another machine or upgrade existing ones. They adapt quickly to changes in demand, giving you an edge in a fast-paced market.Maintenance And Upkeep

People need rest, motivation, and management. This requires resources and attention. Machines, while needing maintenance, can often be managed with scheduled check-ups and regular updates. Imagine a scenario where a machine breaks down. Quick repairs can get it back running without morale issues. With people, repeated stress can lead to burnout, affecting productivity in the long run.Quality And Consistency

Can you always count on consistent quality with manual labor? Human error is natural and can lead to variations in output. Machines excel in delivering consistent results. Once programmed, they perform tasks the same way every time. This consistency boosts customer trust and satisfaction over time.Innovation And Future-proofing

As technology evolves, machines can be upgraded to meet new standards and innovations. This adaptability ensures that your operations remain cutting-edge. Sticking solely to manual labor might mean missing out on technological advancements. Are you prepared for a future where competitors leverage technology for better results? Investing in machine labor might seem daunting initially, but it can lead to substantial long-term gains. Yet, manual labor adds a personal touch that machines can’t replicate. What does your business truly need for sustained growth and efficiency? By weighing these factors, you can make a more informed decision that aligns with your long-term goals.Social Impact

The debate between manual and machine labor often centers on cost. Yet, the social impact is equally important. Machines bring efficiency, but what about the human element? This section explores how each approach affects society.

Impact On Employment

Machines can perform tasks faster than humans. This often leads to fewer jobs. Many people lose their jobs when factories automate. Fewer jobs can lead to higher unemployment rates. This affects families and communities.

Skill Development

Manual labor requires specific skills and training. Workers learn and grow through hands-on experience. Machines can reduce the need for skilled workers. This might limit opportunities for skill development in the workforce.

Community Engagement

Manual labor often fosters strong community ties. Workers interact and build relationships on the job. Machines, however, may reduce this interaction. Less engagement can lead to weaker community bonds.

Economic Disparities

Machine labor can widen economic gaps. Large corporations can afford machines, small businesses may struggle. This creates economic disparities between different regions and sectors.

Environmental Concerns

Machines often require energy and resources. This can lead to environmental issues. Manual labor, on the other hand, is usually more sustainable. The choice between the two affects our planet’s health.

Conclusion

Choosing between manual and machine labor requires careful consideration. Costs differ greatly. Manual labor offers flexibility. Machines provide efficiency and speed. Each option has its advantages. Consider the long-term impact on productivity. Don’t overlook maintenance costs for machines. Think about training costs for workers.

Balancing these factors is crucial. Your decision affects overall business success. Analyze your specific needs thoroughly. Choose what aligns best with your goals. Both options have unique strengths. Weigh the pros and cons carefully. Make an informed choice. Your choice matters for future growth.