Imagine your smart farm equipment working seamlessly, predicting issues before they arise and ensuring that your operations never miss a beat. Sounds like a dream, right?

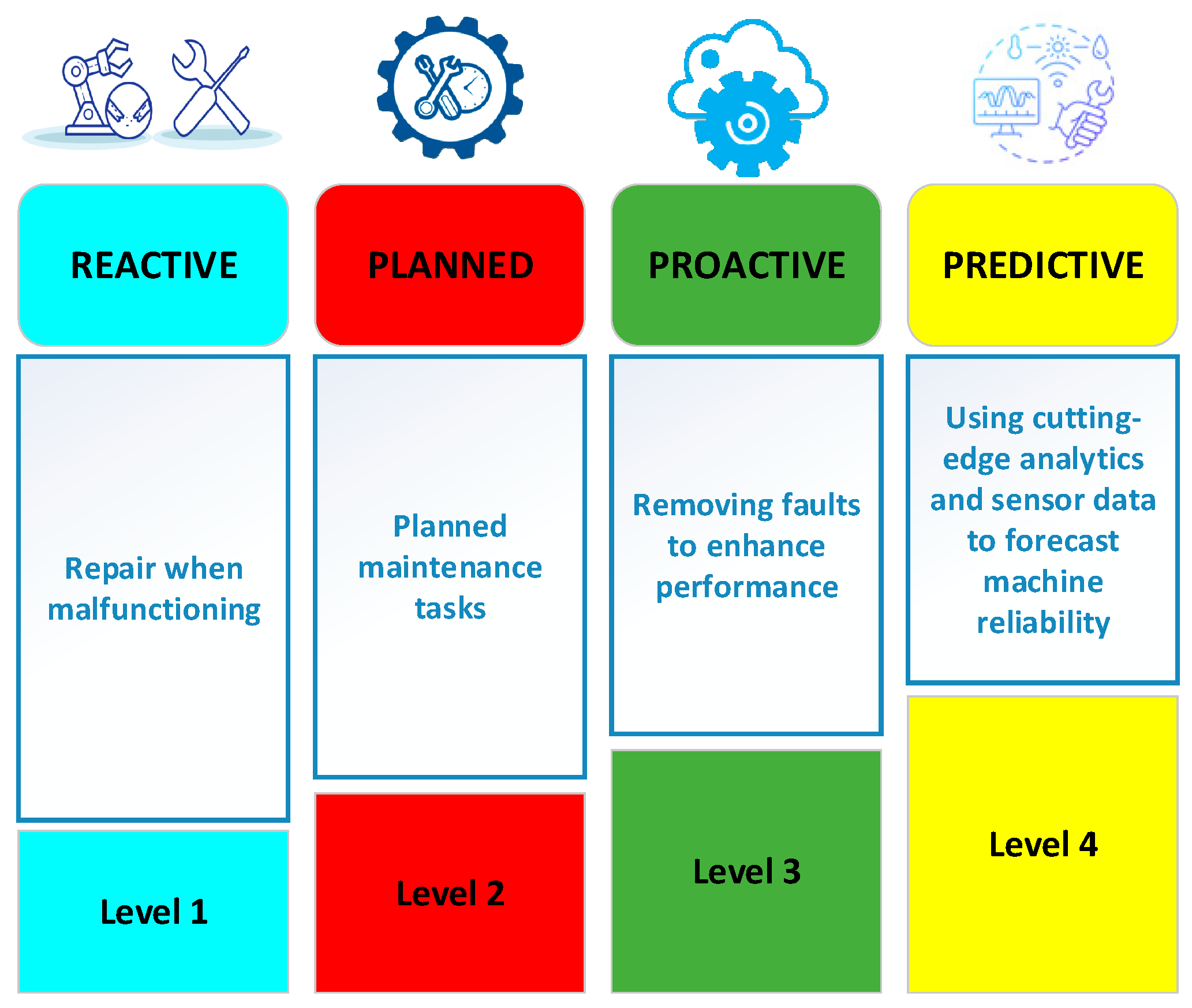

Well, it’s not just a dream anymore, thanks to predictive maintenance. This cutting-edge approach to equipment care could be the game-changer your farm has been waiting for. By harnessing the power of data and advanced technology, predictive maintenance helps you anticipate problems before they happen, saving you time, money, and stress.

Think about it: no more unexpected breakdowns in the middle of a crucial harvest or costly repairs that could have been avoided. Instead, you get peace of mind knowing your machinery is always in top shape. As you dive into this article, you’ll discover how predictive maintenance can revolutionize the way you manage your smart farm equipment. You’ll learn about the tools and techniques that can keep your operations running smoothly and efficiently. Get ready to transform your farm’s future with strategies that put you ahead of the curve.

Benefits Of Predictive Maintenance

Predictive maintenance is transforming the way smart farm equipment operates, offering numerous benefits that are hard to overlook. By using data and technology, you can foresee potential equipment failures and address them before they occur. This not only saves time but also prevents costly disruptions in your farming operations.

Maximized Equipment Efficiency

Imagine your tractor running smoothly all season without hiccups. Predictive maintenance ensures your equipment is always in peak condition. By addressing issues early, you maintain high efficiency, and your equipment performs better over time.

Cost Savings

Why spend more than necessary? Predictive maintenance helps you avoid expensive repairs by catching problems early. Regular checks and timely fixes mean fewer surprise breakdowns, which translates to significant savings on repair costs.

Enhanced Safety

Your equipment is like a partner in your farming journey. Keeping it in top condition ensures safer operations. Predictive maintenance reduces the risk of accidents by identifying potential hazards before they become serious threats.

Extended Equipment Lifespan

Think of your equipment as an investment. Predictive maintenance helps you protect that investment by extending its lifespan. Regular monitoring and maintenance keep your equipment running longer, providing more value over the years.

Improved Productivity

Can you imagine finishing your tasks faster and with less hassle? Predictive maintenance boosts your productivity by minimizing downtime. When your equipment is reliable, you can focus more on farming and less on repairs.

Predictive maintenance isn’t just a buzzword; it’s a practical approach that can significantly benefit your farming operations. Are you ready to harness the power of data and technology to improve your farm’s efficiency? Don’t wait for problems to arise; embrace predictive maintenance and enjoy a smoother, safer, and more productive farming experience.

Technology In Smart Farming

Technology in smart farming is reshaping how we produce food. It’s like giving farmers a new toolbox filled with gadgets that make tasks easier and more efficient. But how does this impact predictive maintenance for smart farm equipment?

Understanding Predictive Maintenance

Predictive maintenance uses technology to foresee equipment issues before they happen. Imagine knowing your tractor will need a new part weeks in advance. This foresight saves time and money.

Smart sensors play a vital role here. They continuously collect data from machinery, like temperature and vibration. This data helps predict when a machine might fail, allowing you to plan maintenance proactively.

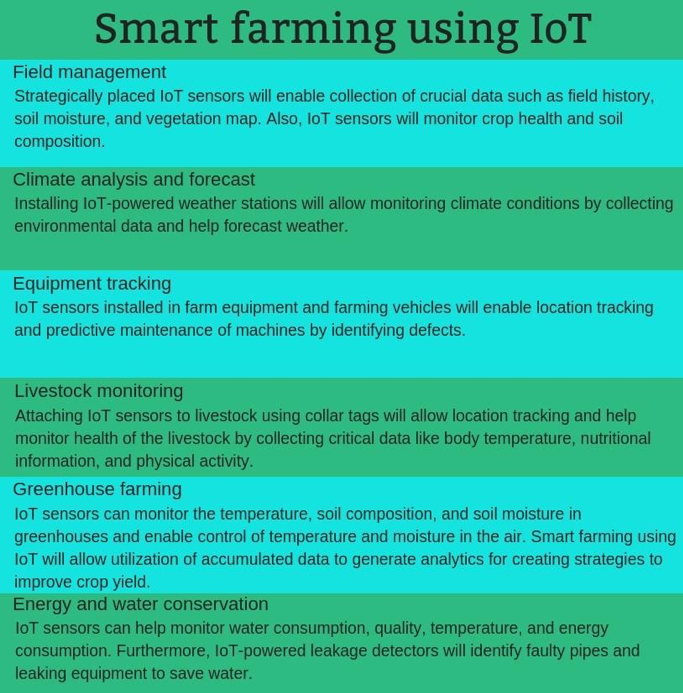

The Role Of Iot In Smart Farming

IoT, or Internet of Things, connects devices to share information. In smart farming, IoT links equipment to farmers’ smartphones or computers. You get real-time updates on your equipment’s health.

Imagine receiving an alert on your phone that your harvester’s engine is overheating. With IoT, you can act immediately, preventing costly downtime.

Benefits Of Predictive Maintenance

Predictive maintenance reduces unexpected breakdowns. Think of how frustrating it is when equipment fails at peak harvest time. By anticipating issues, you keep your operations smooth.

This approach also extends the lifespan of your equipment. Regular maintenance based on real data prevents wear and tear. You invest less in repairs and replacements.

Challenges And Solutions

Implementing predictive maintenance isn’t always straightforward. You might wonder if the technology is worth the investment. Consider the long-term savings and efficiency gains.

Training can be another hurdle. Equip your team with the knowledge to interpret data and act on it. Workshops and tutorials can make this transition smoother.

Your Next Steps

Are you ready to embrace technology in your farming operations? Start by evaluating your current equipment. Identify what can benefit most from predictive maintenance.

Research tools and platforms that fit your farm’s needs. Engage with other farmers who have adopted smart farming techniques. Share experiences and tips to make informed decisions.

Technology is changing farming, and predictive maintenance is a key part of this transformation. How will you leverage it to boost your farm’s productivity?

Challenges In Implementation

Farm equipment needs reliable data for predictive maintenance. Integrating sensors and software can be complex. Training farmers to use new tech is crucial.

Predictive maintenance is transforming the way smart farm equipment operates, offering significant benefits such as reduced downtime and cost efficiency. However, implementing predictive maintenance is not without challenges. These obstacles can hinder the seamless integration of this technology into everyday farming practices. As you navigate this journey, understanding these challenges is crucial.Data Collection And Quality

Gathering high-quality data is the backbone of predictive maintenance. Smart equipment requires accurate data to predict failures effectively. However, many farmers struggle with inconsistent data collection methods. You might face issues with outdated sensors, or equipment not properly calibrated. Ensuring data quality is essential. Regularly update sensors and check for calibration issues.Connectivity Issues

Smart equipment relies heavily on internet connectivity. Yet, many farms are located in remote areas with limited access. Poor connectivity can disrupt data transmission. This can lead to inaccurate predictions and missed opportunities for maintenance. Consider investing in better connectivity solutions. Satellite internet or dedicated data networks might be worth exploring.High Initial Costs

The cost of implementing predictive maintenance technology can be daunting. Initial investments in sensors, software, and training are substantial. But, think of it as a long-term investment. Savings from reduced downtime and maintenance costs can outweigh the initial expenses. Look for government grants or subsidies. These can help alleviate some of the financial burdens.Technical Expertise

Operating smart farm equipment requires a certain level of technical know-how. Farmers might not always have the expertise to manage this technology. Do you feel overwhelmed by the technology? You’re not alone. Many farmers face this challenge. Consider training programs or hiring skilled personnel. This can bridge the gap and ensure smooth operations.Resistance To Change

Change is never easy, especially in traditional farming environments. Some farmers might be resistant to adopting new technologies. Fear of the unknown can be a significant barrier. But, embracing change can lead to numerous benefits. Engage with other farmers who have implemented predictive maintenance. Their experiences can provide valuable insights and ease your transition. Predictive maintenance is the future of smart farming, but it comes with its set of challenges. By addressing these hurdles head-on, you can pave the way for a more efficient and productive farming operation. Are you ready to take the leap?

Future Trends In Farm Equipment Maintenance

Smart farm equipment uses predictive maintenance to foresee issues before they arise. Sensors and data analytics help identify potential problems. This reduces downtime and repair costs.

Predictive maintenance is changing how farmers care for their equipment. Using technology, it helps predict when machines need fixing. This saves time and money. As technology grows, so do the ways we maintain farm tools. Let’s explore some trends shaping the future of farm equipment maintenance.1. The Rise Of Iot In Agriculture

The Internet of Things (IoT) connects devices for smarter data collection. In farming, IoT sensors monitor equipment health. They provide real-time data on machine performance. Farmers get alerts before issues arise. This prevents unexpected breakdowns. IoT integration means less downtime and better productivity.2. Artificial Intelligence And Machine Learning

AI and machine learning enhance predictive maintenance. These technologies analyze vast amounts of data quickly. They detect patterns that humans might miss. Machines learn from past behaviors to predict future issues. AI-driven insights help farmers plan maintenance schedules. This ensures machines run smoothly.3. Drone Technology For Equipment Inspection

Drones offer a new way to inspect farm equipment. They provide a bird’s-eye view of machinery. Drones capture images and videos of equipment parts. They help identify wear and tear early. This early detection can save costly repairs. Drone inspections are fast and efficient.4. Cloud-based Maintenance Solutions

Cloud technology stores and processes maintenance data. Farmers access data from anywhere with internet access. Cloud solutions offer secure, scalable storage. They enable easy sharing of maintenance records. This helps in making informed decisions quickly. Cloud-based systems are user-friendly and cost-effective.5. Enhanced Data Analytics

Advanced data analytics improve maintenance strategies. They convert raw data into actionable insights. Farmers use these insights to enhance equipment life. Analytics provide a clear view of machine health. This guides timely repairs and parts replacement. Enhanced analytics reduce maintenance costs.6. Sustainability And Eco-friendly Practices

Sustainability is becoming crucial in agriculture. Predictive maintenance supports eco-friendly farming. It reduces waste by extending equipment life. Proper maintenance decreases emissions from malfunctioning machines. Sustainable practices protect the environment. They also promote efficient resource use. The future of farm equipment maintenance is bright. Emerging trends promise smarter, more efficient farming. As technology advances, farmers will benefit greatly.Conclusion

Smart farm equipment benefits greatly from predictive maintenance. It reduces downtime and saves costs. Farmers can plan ahead with accurate data. This leads to efficient farming operations. Predictive maintenance ensures equipment runs smoothly. It helps prevent unexpected breakdowns. Farmers gain peace of mind.

Technology continues to evolve in agriculture. Monitoring systems make farming smarter. These tools support sustainable practices. They optimize resources and enhance productivity. Predictive maintenance is key for future-ready farms. It fosters growth in the agricultural sector. Embrace these advancements for better farm management.

Smart farms thrive with well-maintained equipment.