Are you considering investing in machinery for your business but feeling overwhelmed by the potential costs? You’re not alone.

Understanding the costs of machinery ownership is crucial for making informed decisions. It’s not just about the initial purchase price; it’s about the hidden expenses that can catch you off guard. Think about maintenance, insurance, and even downtime costs. You want to ensure your investment pays off, don’t you?

By comprehending these factors, you can avoid unexpected financial burdens and maximize your profit potential. Ready to learn how to safeguard your investment and keep your business running smoothly? Dive into this article and arm yourself with the knowledge you need to make the best decision for your business’s future.

Initial Purchase Costs

Understanding the costs of machinery ownership starts with the initial purchase costs. These costs are often the most significant part of owning machinery. It’s crucial to grasp what factors contribute to these expenses. A clear understanding helps in budgeting and planning effectively.

Types Of Machinery

The type of machinery affects the initial cost. Large machinery like bulldozers usually costs more than smaller tools. Each type has its unique price range. Knowing these differences is essential for making informed decisions.

Brand Considerations

The brand of machinery can influence the purchase cost. Reputable brands often have higher prices. They promise quality and durability. Lesser-known brands may offer lower prices. Buyers should weigh the cost against potential benefits.

New Vs. Used Machinery

Buying new machinery typically costs more. New models come with warranties and modern features. Used machinery offers lower initial costs. It may lack advanced features. Consider the condition and history before deciding.

Customization Options

Customization can increase initial purchase costs. Tailoring machinery to specific needs often requires extra spending. Custom features can improve efficiency. It’s important to assess the necessity and value of these options.

Maintenance And Repair Expenses

Understanding the costs of machinery ownership is crucial for anyone involved in manufacturing or construction. One key aspect that often gets overlooked is the maintenance and repair expenses. These costs can significantly impact your budget, yet they’re essential to keep your machinery running smoothly. By being proactive, you can mitigate unexpected expenses and extend the lifespan of your equipment.

Routine Maintenance: The Lifeline Of Your Machinery

Routine maintenance is like a regular health check-up for your machines. It keeps them in top condition and prevents minor issues from turning into costly repairs. Think of it as an investment in the longevity of your equipment.

Creating a maintenance schedule helps in staying organized. Keep track of when each machine needs servicing and what specific tasks are required. This systematic approach not only saves money but also minimizes downtime.

Unexpected Repairs: Prepare For The Unpredictable

Despite your best efforts, machines can break down unexpectedly. It’s wise to set aside a budget for unforeseen repairs. This financial cushion ensures you’re not caught off guard when something goes wrong.

Consider this: What would happen if a vital piece of equipment suddenly failed? Planning ahead can prevent panic and ensure you’re ready to handle emergencies efficiently.

Diy Vs. Professional Repairs: Making The Right Choice

Sometimes, you might be tempted to fix machinery issues yourself to save money. However, this approach can backfire if you’re not experienced. Attempting complex repairs without the right skills can lead to more damage.

Evaluate the complexity of the repair and your own expertise. If it’s beyond your skill level, hiring a professional can save you from costly mistakes. It might be pricier upfront, but it ensures the job is done correctly.

Tracking Costs: Understanding Where Your Money Goes

Keeping a detailed record of maintenance and repair expenses helps you understand your spending patterns. This data can guide future budgeting and help identify areas for cost reduction.

Use software or spreadsheets to log every expense related to your machinery. This practice not only aids in financial planning but also provides insights into the long-term cost-effectiveness of your equipment.

Long-term Planning: Safeguarding Your Investment

Think about the long-term benefits of regular maintenance. A well-maintained machine not only runs efficiently but also retains its value better. This can be advantageous if you decide to sell or upgrade.

Ask yourself: Are you planning for the future of your machinery? Taking steps now can ensure you’re maximizing your investment and avoiding unnecessary losses.

Operational And Energy Costs

When it comes to machinery ownership, operational and energy costs can sometimes be overlooked. Yet, they are critical components that influence your bottom line. Understanding these costs not only helps in budgeting but also in making informed decisions about equipment efficiency.

Understanding Operational Costs

Operational costs are the day-to-day expenses associated with running machinery. These include labor, maintenance, and supplies needed to keep machines running smoothly. Are you tracking these costs regularly?

Neglecting operational expenses can lead to unexpected financial burdens. A well-maintained machine not only lasts longer but also operates more efficiently. Regular maintenance checks can save you time and money in the long run.

Consider setting up a schedule for routine inspections. This proactive approach ensures that minor issues don’t escalate into costly repairs. How much could you save by preventing a major breakdown?

Energy Costs: The Hidden Expense

Energy consumption is another significant cost of machinery ownership. Machines that consume excessive energy can inflate your utility bills. Have you evaluated the energy efficiency of your equipment?

Switching to energy-efficient models can lead to substantial savings. Look for machines with energy-saving features and certifications. Are you aware of any government incentives for upgrading to energy-efficient equipment?

Monitoring energy usage can highlight inefficiencies. Simple changes, like adjusting machine settings, can reduce energy consumption. What small adjustments could you make today to cut down on energy costs?

Balancing Operational And Energy Costs

Balancing these costs requires strategic planning. Invest in training for your staff to optimize machine use. Do your employees know the best practices for reducing wear and tear?

Encourage a culture of accountability where everyone is aware of the impact of their actions on costs. Could fostering such an environment lead to overall cost reductions?

Lastly, always compare the cost of operation versus the potential savings from energy efficiency. This will guide you in making smart investment decisions. Are you ready to take control of your machinery costs?

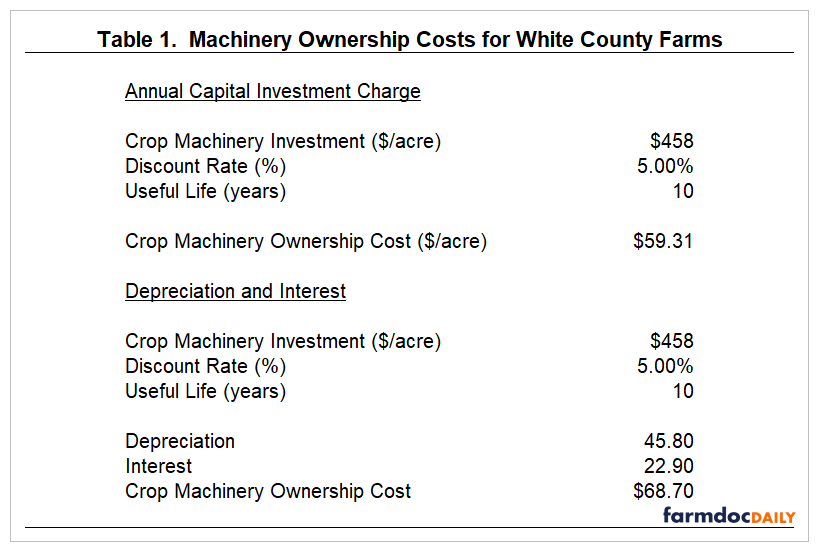

Depreciation And Resale Value

Machinery ownership comes with unique financial considerations. Depreciation and resale value play significant roles. They impact the overall cost and return on investment. Understanding these aspects helps in making informed decisions.

What Is Depreciation?

Depreciation refers to the reduction in machinery value over time. It occurs due to wear and tear. Every machine loses value as it ages. This is a natural process in asset management.

Understanding depreciation helps in budgeting. It affects both current and future financial planning. Businesses must account for this in their financial statements.

Factors Influencing Depreciation Rates

Several factors influence how quickly machinery depreciates. Usage intensity is a major factor. Frequent use accelerates wear and tear. This leads to faster depreciation.

Technological advancements also play a role. Newer models make older machines obsolete. This increases their depreciation rate.

Understanding Resale Value

Resale value is the estimated price a machine can fetch. It reflects the market demand for used equipment. High resale value indicates good demand.

Several factors affect resale value. Brand reputation is one. Reliable brands often retain value longer. Maintenance history also impacts resale value. Well-maintained machinery attracts better offers.

Strategies To Maximize Resale Value

Regular maintenance can boost resale value. Document all service and repairs. This builds buyer confidence.

Keeping machinery clean is essential. Appearance matters in used equipment sales. Also, consider selling before major repairs are needed. This can ensure a higher return.

Conclusion

Owning machinery involves understanding various costs. Initial purchase is just the start. Maintenance, repairs, and fuel add to expenses. Depreciation affects long-term value. Financing can impact monthly budgets. Proper planning helps manage these costs effectively. Compare different machinery options. Consider the total cost of ownership, not just the price.

Making informed decisions saves money over time. Awareness of all costs avoids financial surprises. Smart management ensures better returns on investment. Machinery ownership can be rewarding with careful consideration. A clear understanding leads to better financial outcomes. Make wise choices for your machinery needs.