Imagine a world where your equipment tells you it needs a tune-up before it even breaks down. No more unexpected failures, no more costly downtimes.

This isn’t a dream—it’s the reality of using AI for predictive maintenance in your equipment. You might wonder how this is possible, or how it could benefit you and your business. Well, you’re about to discover the powerful impact AI can have on predicting equipment needs, saving you time, money, and stress.

With AI on your side, you’re not just maintaining your equipment; you’re optimizing it for peak performance. Get ready to explore a transformative approach that could revolutionize how you manage your machinery. Dive deeper, and see how AI can become your ultimate maintenance ally.

Ai In Equipment Maintenance

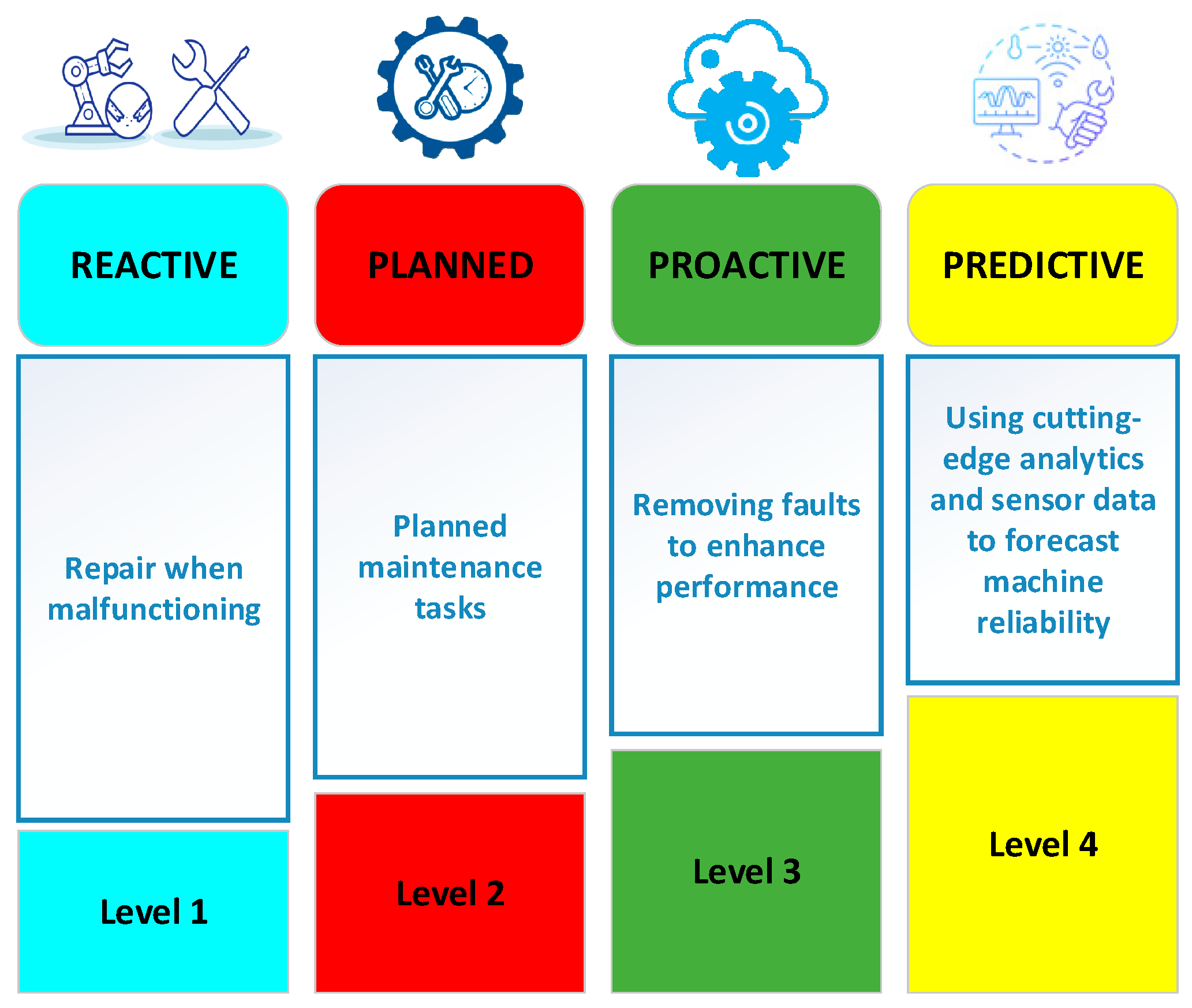

AI is transforming equipment maintenance, enhancing efficiency and reliability. Predictive maintenance uses AI to foresee equipment issues before they occur. This approach saves time and resources, preventing unexpected breakdowns. AI analyzes data, predicting patterns of wear and tear. Thus, it ensures equipment runs smoothly, reducing downtime.

AI offers several benefits in equipment maintenance. It improves the accuracy of predictive maintenance. AI systems can analyze vast amounts of data quickly. This helps in identifying potential faults early. Machines learn from past failures, improving their predictive ability. Maintenance schedules become more precise, reducing unnecessary checks.

How Ai Predicts Equipment Failures

AI uses algorithms to process data from sensors. These sensors are attached to equipment. They collect data on temperature, vibration, and pressure. AI analyzes this data to detect abnormalities. It predicts failures before they happen. This allows maintenance teams to act promptly.

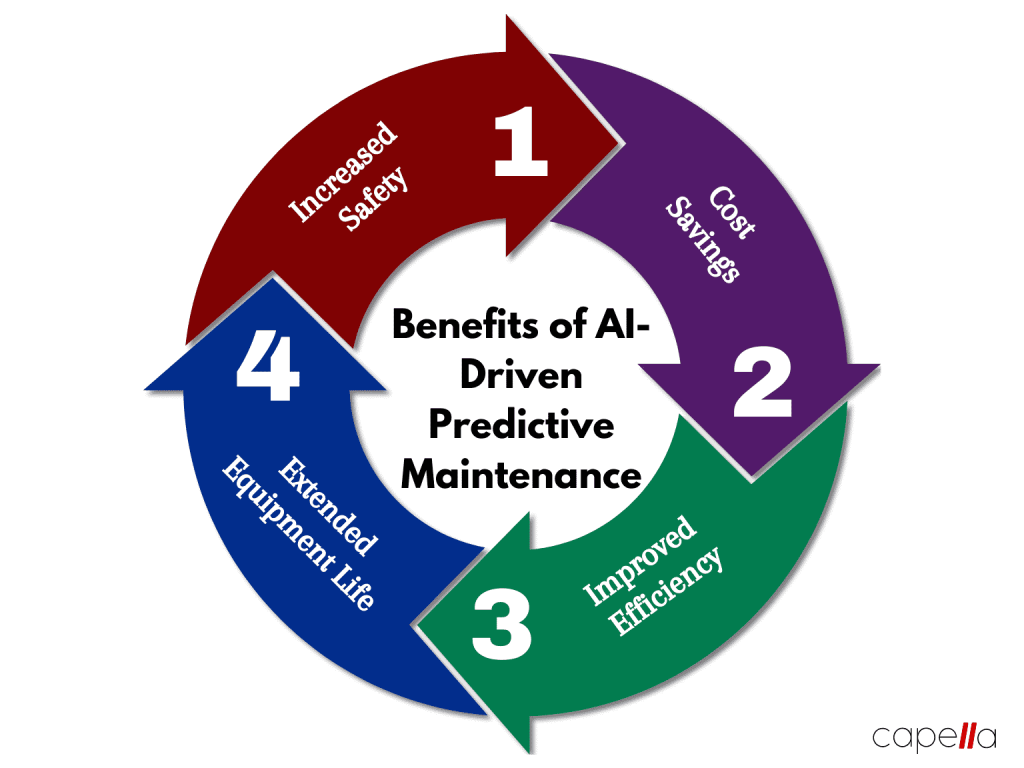

Benefits Of Ai In Maintenance

AI reduces maintenance costs significantly. It minimizes downtime, enhancing productivity. Equipment lasts longer due to timely interventions. Maintenance becomes more efficient, freeing up resources. AI also improves safety by preventing unexpected equipment failures. This protects workers and saves on repair costs.

Implementing Ai In Maintenance Systems

Integrating AI into existing systems requires planning. Companies must choose suitable AI platforms. Training is essential for staff to use AI tools effectively. Data management is crucial for accurate predictions. Regular updates keep AI systems efficient. Collaboration between IT and maintenance teams ensures smooth implementation.

Benefits Of Predictive Maintenance

AI helps predict when equipment might fail. It saves time and money by preventing breakdowns. Regular checks aren’t needed as often. Equipment lasts longer with fewer repairs.

Predictive maintenance is revolutionizing how industries approach equipment upkeep. By leveraging AI, companies are moving from reactive to proactive strategies. This shift not only saves time and money but also enhances equipment reliability and lifespan. How would your business change if you could predict failures before they happen?Efficiency And Cost Savings

Imagine a world where unexpected equipment breakdowns are a thing of the past. Predictive maintenance uses AI to forecast when a machine is likely to fail. This allows you to schedule repairs during downtime rather than dealing with costly emergencies. You save money on repairs and avoid lost productivity.Improved Equipment Longevity

When you maintain equipment before it breaks, you extend its lifespan. AI analyzes data to determine optimal maintenance schedules. Regular maintenance reduces wear and tear, ensuring machines operate smoothly for longer periods. This means fewer replacements and more savings for your business.Enhanced Safety

Safety is paramount in any industry. Predictive maintenance helps prevent accidents caused by faulty equipment. By addressing issues before they escalate, you create a safer working environment. Workers can focus on their tasks without worrying about sudden equipment failures.Data-driven Decisions

AI provides valuable insights from the data collected during equipment operations. You gain a deeper understanding of your machines, allowing you to make informed decisions. By analyzing patterns and trends, you can optimize performance and efficiency. Are you currently using data to enhance your operations?Reduction In Downtime

Downtime can be a major headache for businesses. Predictive maintenance minimizes downtime by ensuring equipment is always ready for action. AI predicts potential issues, allowing you to address them before they cause disruptions. This leads to smoother operations and increased productivity.Customization And Flexibility

Every business has unique needs, and predictive maintenance can be tailored to fit yours. AI systems are adaptable, allowing you to focus on specific equipment or processes. This flexibility ensures that you get the most out of your investment. How could customization improve your maintenance strategy? Predictive maintenance is not just a technological advancement; it’s a practical solution with tangible benefits. By embracing AI for predictive maintenance, you can transform how you approach equipment care. Are you ready to make the shift?Ai Tools And Techniques

AI tools enhance predictive maintenance by analyzing data to foresee equipment issues. This approach minimizes downtime and extends machinery lifespan, ensuring smooth operations. Effective use of AI techniques allows timely interventions, saving costs and boosting productivity across industries.

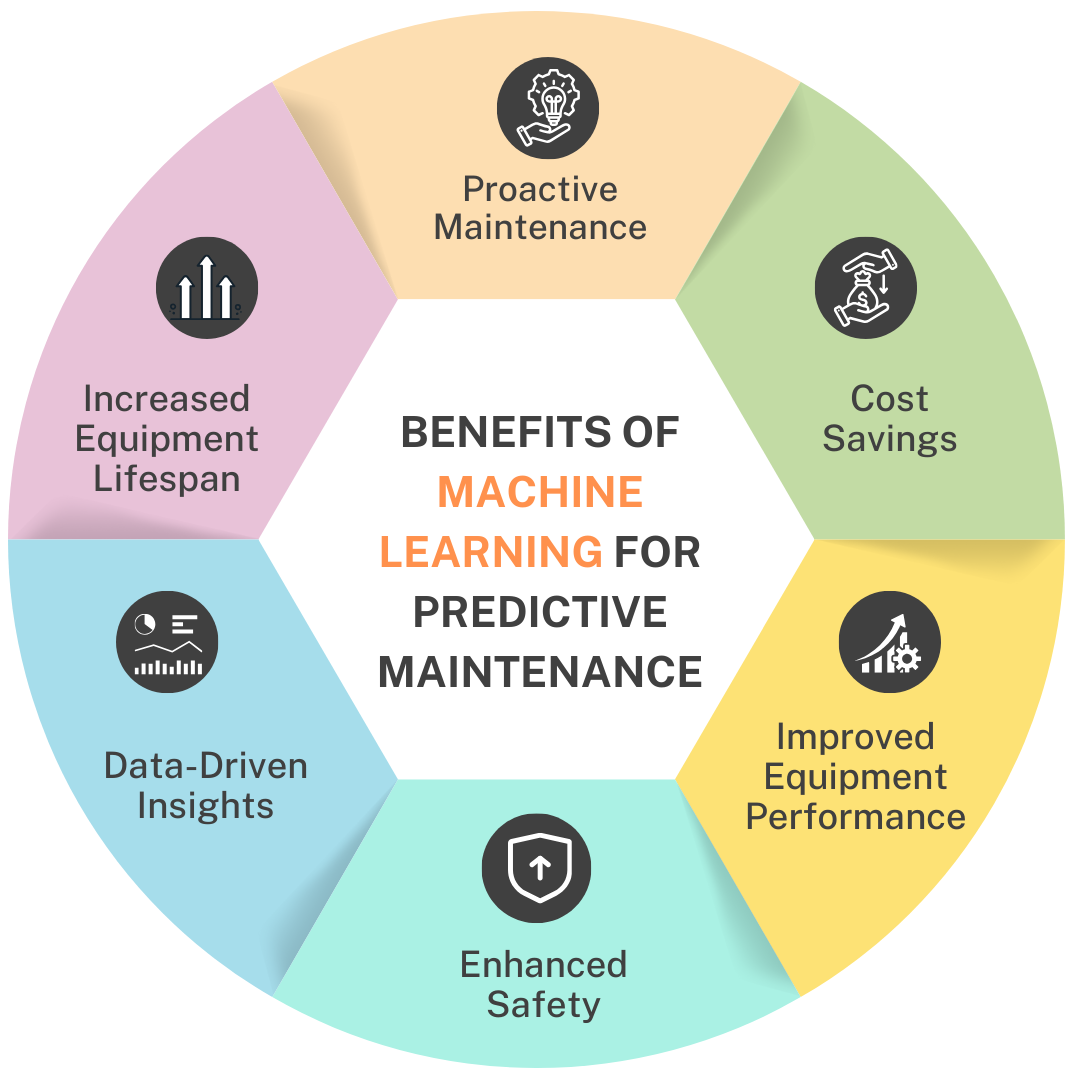

Predictive maintenance using AI is transforming how industries manage equipment. By leveraging AI tools and techniques, companies can anticipate equipment failures before they happen. This proactive approach not only saves time and money but also boosts productivity and safety. Let’s dive into some of the AI tools and techniques making this possible.Understanding Machine Learning Algorithms

Machine learning algorithms are at the heart of AI-driven predictive maintenance. These algorithms analyze data from equipment sensors to identify patterns that indicate potential failures. Imagine your equipment could talk to you, warning you before it breaks down. For example, supervised learning models use historical data to predict future failures. If you have data on previous equipment breakdowns, these models can help foresee similar issues. This means less downtime and more peace of mind for you.The Role Of Iot In Data Collection

The Internet of Things (IoT) plays a crucial role in predictive maintenance. IoT devices collect real-time data from equipment, providing a continuous stream of information. This data feeds into AI models, making predictions more accurate. Think of IoT as a bridge connecting your equipment to your decision-making process. By using IoT, you can have a constant pulse on the health of your machinery. This real-time insight allows you to act fast and avoid costly repairs.Data Analysis And Visualization Tools

Data analysis and visualization tools are essential for interpreting the vast amounts of data collected. These tools help you make sense of complex data sets, turning them into actionable insights. Visual dashboards can show you which machines need attention at a glance. This helps prioritize maintenance tasks effectively. By using these tools, you can ensure that your maintenance efforts are targeted and efficient.Utilizing Predictive Analytics Software

Predictive analytics software is a game-changer for maintenance teams. This software uses AI to predict when equipment is likely to fail. It offers recommendations on the best maintenance actions to take. Imagine having a maintenance assistant that never sleeps. This software can work tirelessly, analyzing data and providing you with timely alerts. With this tool, maintenance becomes a strategic, rather than reactive, process.Challenges And Considerations

While AI tools offer significant advantages, they come with challenges. Integrating AI into existing systems can be complex. Data quality and privacy are also key concerns. It’s essential to have a clear strategy for implementing these tools. Consider the specific needs of your equipment and organization. Are you ready to embrace this technology? Making informed decisions will ensure you get the most out of AI in predictive maintenance.Future Trends In Predictive Maintenance

AI makes predictive maintenance for equipment smarter. It helps predict when machines might fail. This saves time and reduces costs.

Predictive maintenance is rapidly evolving, thanks to the integration of AI technologies. With the future of predictive maintenance on the horizon, understanding how AI will shape these changes is crucial. AI in predictive maintenance promises not just efficiency but also innovation. From advanced data analytics to machine learning models, the future looks bright. But what does this mean for your equipment and maintenance strategy?Advancements In Sensor Technology

The role of sensors in predictive maintenance is becoming more significant. Modern sensors are smaller and smarter. They can track a wide range of parameters, from temperature to vibration frequency. Imagine having sensors that predict equipment failure days before it happens. This trend is transforming how you approach maintenance.Integration With Iot

IoT is enhancing predictive maintenance through connectivity. Your equipment can now communicate with maintenance systems seamlessly. This integration allows real-time data collection and analysis. Picture your machines sending alerts to your phone about potential issues. This proactive approach reduces downtime and increases efficiency.Machine Learning Models

Machine learning is setting a new standard in predictive analytics. These models learn from past equipment behavior to predict future issues. They evolve and adapt, making predictions more accurate over time. Think about using machine learning to anticipate maintenance needs, saving time and resources. Are you ready to embrace this technology?Data-driven Insights

Data is the powerhouse behind AI-driven predictive maintenance. You can leverage vast amounts of data for actionable insights. This data helps in understanding patterns and anomalies in equipment performance. Consider using these insights to make informed decisions about your maintenance strategy. How are you utilizing data to improve your operations?Automation And Robotics

Automation is simplifying predictive maintenance tasks. Robotics can perform routine maintenance, freeing up human resources for complex tasks. Imagine robots diagnosing and repairing equipment autonomously. This trend is reshaping the maintenance landscape, offering efficiency and precision.User-friendly Interfaces

User interfaces are becoming more intuitive and accessible. You no longer need to be an expert to navigate predictive maintenance software. These interfaces are designed to be user-friendly, providing clear insights at a glance. Have you tried using these tools to streamline your maintenance processes?Cost Efficiency

Predictive maintenance with AI is proving cost-effective. It minimizes unexpected breakdowns and extends equipment life. The initial investment in AI tools pays off with reduced maintenance costs. Consider how cost savings can be redirected towards innovation and growth. Are you capitalizing on these financial benefits? The future of predictive maintenance is filled with opportunities for improvement and efficiency. As AI continues to advance, your equipment maintenance strategy can become more proactive and informed. With these trends, you have the power to transform your approach and reap the benefits. Are you prepared to take advantage of these technological advancements?

Conclusion

Embracing AI for predictive maintenance boosts equipment efficiency. It reduces downtime and saves costs. This approach helps identify issues early. Maintenance becomes proactive, not reactive. Companies enjoy longer equipment life. They also see improved safety and productivity. AI tools are becoming easier to use.

Businesses can start small and scale up. The future of maintenance looks promising with AI. Investing in this technology makes sense. It offers a competitive edge in today’s market. AI-driven maintenance is no longer a luxury. It’s a smart choice for forward-thinking organizations.